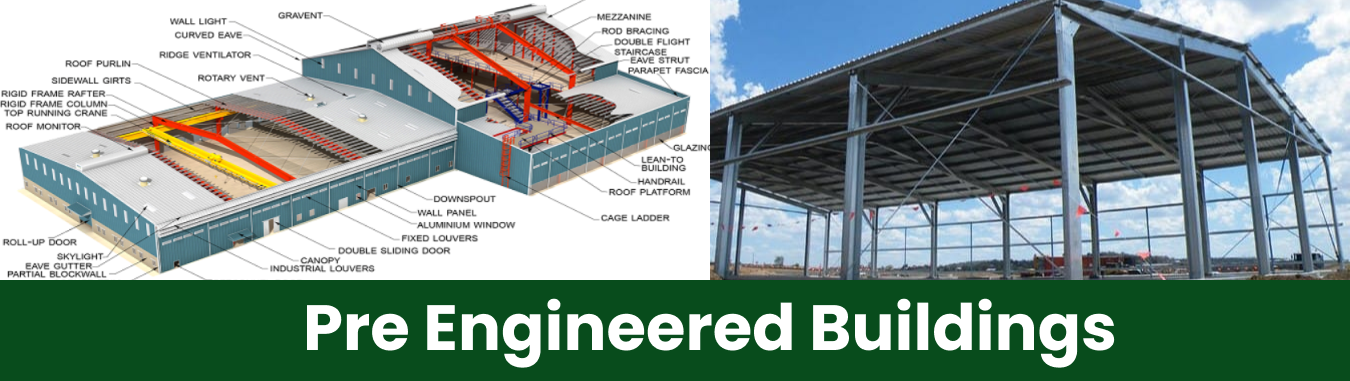

PEB are up to 30% lighter than conventionally designed steel structures due to efficient use of steel. Primary framing members are tapered (varying depth) built-up sections, with larger depths in the areas of highest stresses and internal forces. These sections are engineered to maximise optimal section usage. Secondary members are light gage (light weight) roll- formed (low labour cost) “Z” or “C” shaped members.

In the conventional design of steel structures, primary steel members are selected from standard hot rolled “I” sections, which are, in many segments of the portal frame, heavier than what is required, when looking at internal forces. Members have constant cross-sections regardless of the varying magnitude of the local (internal) stresses along the member length.